Prototyping

JS offers responsive prototyping services!

JS offers responsive prototyping services! Most often we are able to get to an improved design for our customers that will require less revisions; therefore, saving time and money related to your overall product development lifecycle.

Given the nature of flexible circuits, we believe that it is extremely important to develop PROTOTYPES at the same facility that will produce your production parts. In doing so, there will be no surprises related to performance, as we are using the same materials, equipment, and processing methods for the prototype build that will be utilized in production.

We understand the importance of speed, at the same time, those that utilize the same facility for prototyping and production often save time and costs related to the overall product development lifecycle; as one can efficiently transition to production.

Note: Lead times are depending upon complexity, material needs, and for circuit assemblies on component availability/lead time.

Component Procurement

While our business centers on producing PCB that meet your needs, JS often takes on the additional challenge of sourcing the add-on components required for your subassembly.

While our business centers on producing PCB that meet your needs, JS often takes on the additional challenge of sourcing the add-on components required for your subassembly. From off the shelf components to custom manufactured components, plastics, heat sinks and beyond, JS can be your resource during prototyping and production to source the components required for your program.

JS employs a stringent process when sourcing components inclusive of our proprietary matrix based sourcing system that allows us to compare costs and lead times against several suppliers. This matrix based systems allows JS to come up with best case scenarios for our customers related to cost and lead time. We then weigh the results against our customers most pressing requirements to develop the best case scenario for obtaining components in support of meeting our customers program requirements.

Testing Services

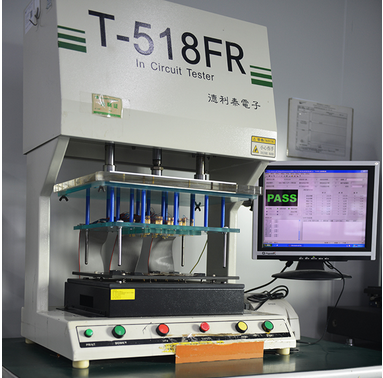

ELECTRICAL TEST (BARE CIRCUITS)

ELECTRICAL TEST (BARE CIRCUITS)Flying probe, universal grid and dedicated test systems

100% netlist driven test processes

Netlist formats: IPC D356, ODB++, CAD generatedIPC 9252 class 1,2 and 3 testing

In-house test program generation and fixture manufacturing

Test parameters:Continuity > 0.1 OhmsIsolation < 100 meg OhmsVoltage 10 – 250 VDCCurrent 20 milliohms maxHipot testing: dielectric breakdown, dielectric withstanding, insulation resistanceImpedance testing

ELECTRICAL TEST (ASSEMBLIES)Full in-house functional test capabilities: connectorized, digital and analog productIn-house test program generation and fixture manufacturing

RELIABILITY TESTINGFull in-house reliability and failure analysis capabilitiesBare and assembled productPlating and surface finish analysisMechanical testing (shear, pull, flexure and tensile)In-house scanning electron microscope (SEM)X-ray inspection

Inventory Stocking

JS not only provides inventory stocking, we encourage our customers to take advantage this service. Inventory stocking programs allow JS to coordinate with our customers in managing finished part inventory and stocking while supplying the parts to our customers with JIT (just in time) deliveries.

JS not only provides inventory stocking, we encourage our customers to take advantage this service. Inventory stocking programs allow JS to coordinate with our customers in managing finished part inventory and stocking while supplying the parts to our customers with JIT (just in time) deliveries. This also allows JS to keep safety stock in place if/as requested for those customers who may have certain parts or products where forecasting is difficult and demand can rise dramatically without forewarning.

JS will stock parts in our warehouse and ship JIT in a coordinated fashion with our customers to their desired location.

Program Management

JS prides itself on our ability to support our customers with overall program management for new product development efforts to long term production programs.

JS prides itself on our ability to support our customers with overall program management for new product development efforts to long term production programs.JS’s New Product Development Teams – JS’s Program Managers, Application Engineers, CAD team and Support Staff are all geared to support our customers in new product development efforts. FCT’s focus is on the bare flex/rigid flex circuit and/or for sub-assemblies including your bill of materials (BOM) and component procurement, prototyping, pre-production runs and support in providing overall program management to assure that the process runs smoothly. Once our customers get to a point where their associated part moves to production; FCT transitions this part to our specialized Production/Blanket Team.

JS Production/Blanket Program Management team – JS’s Production/Blanket Team is specifically in place to support customers where the part has moved to production/blanket status. This team provides overall program management in coordinating with our customers. This includes ordering the components for sub-assembly, assuring components get to JS on time, coordinating JS production schedule/builds, coordinating our inventory and stocking program, and meeting ship dates and JIT production schedules for our customers.