ASSEMBLY

ASSEMBLY

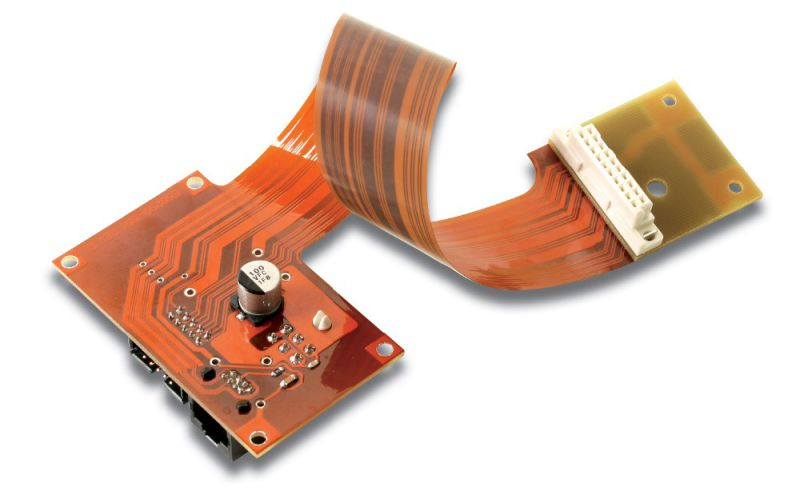

Our assembly facility offers: Full turnkey- Prototype, low, medium and high volume quantities ISO 9001: 2015 & ISO 13485: 2016 certified Standards: IPC-A-610, J-STD-001, IPC-HDBK-001 Seven complete SMT lines 9 modern Electronic Workshops Reliability Lab Testing Services Dedicated workshops for specific customers in support of meeting high-volume programs and dedicated workshops that are set up for high mix - lower volume programs. |

Our Assembly Capabilities Include: Full SMT lines Leading expertise in placement of components onto board Hot-Bar soldering Fine pitch connector of 0.3mm (12mils) Passive component 0201 (0603) QFP (quad flat package) / IC / fine pitch (20 mils) BGA Assembly - smallest pitch 0.25mm 01005 or above - component placement Selective Wave Solder ACF/ACP bonding (anisotropic conductive film or paste bonding) Wire Harness - added to circuit assembly Sonic welding or other attachment methods and much more… JS will also design and procure specialized equipment to support overall program requirements if/as needed and more… |